Our Products

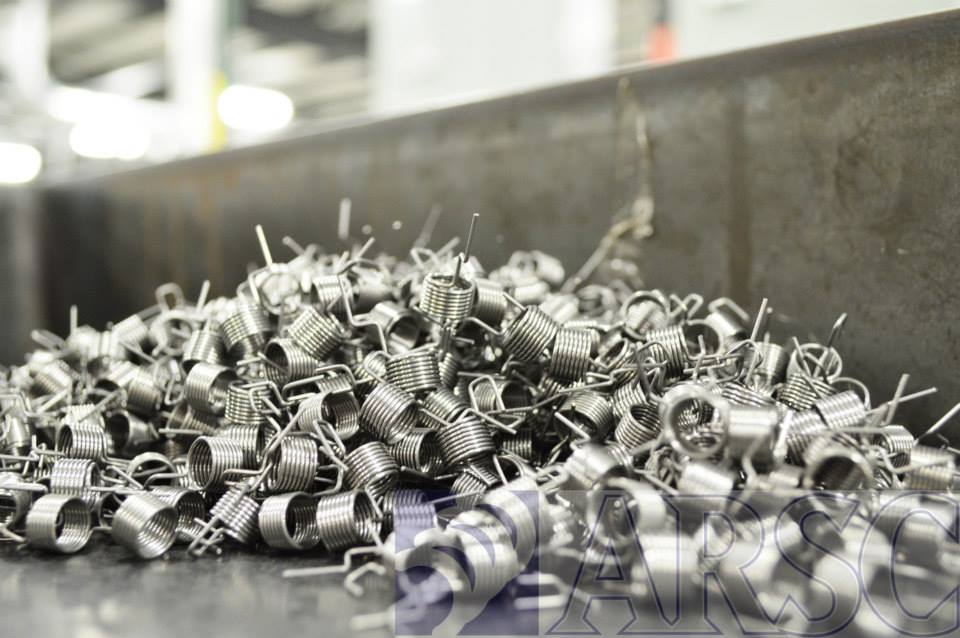

Springs

Precision Springs for Every Application

Wireforms

Precision Springs for Every Application

Why We're Different

Precision Measurement & Metrology

Using advanced telecentric video measuring systems, All-Rite verifies spring geometry and tolerances down to micron-level accuracy. Every coil is validated to ensure perfect consistency, repeatability, and 0 PPM-level reliability

Advanced CNC Coiling & Forming

Our state-of-the-art Shinko and Torrington coilers, paired with non-contact gaging and automated stress relief ovens, produce springs and wireforms with unmatched precision and performance.

Scientific Approach to Spring Design

We take the “black art” out of spring manufacturing through data-driven engineering and stress modeling. This approach refines performance variables and ensures every part behaves exactly as intended in its end application.

Engineering Partnership, Not Just Production

You own the design, we provide the expertise. Our team collaborates directly with your engineers to translate your unique specifications into manufacturable, high-performance parts that meet critical functional requirements.

Automation & Quality Assurance

From inline camera inspection to robotic handling, we integrate automation at every stage to deliver accuracy, speed, and scalability without compromise.

Reshoring-Ready Manufacturing

When offshore suppliers fall short, we deliver U.S.-based precision manufacturing solutions that restore control, quality, and confidence in your supply chain.